Power solutions designers

System Engineering

Our team of highly experienced engineers is specialized in power electronics for electric mobility applications. We can help our customers tackle their power conversion challenges such as on-board chargers (OBC), DC-DC converters motor controllers and control boards.

Our services range from feasibility studies to integration and manufacturing, design your electronics architecture systems such as onboard chargers and DC-DC converters. We provide feasibility study, to understand and size your needs in power supplies, motor controllers and control boards.

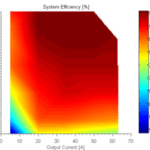

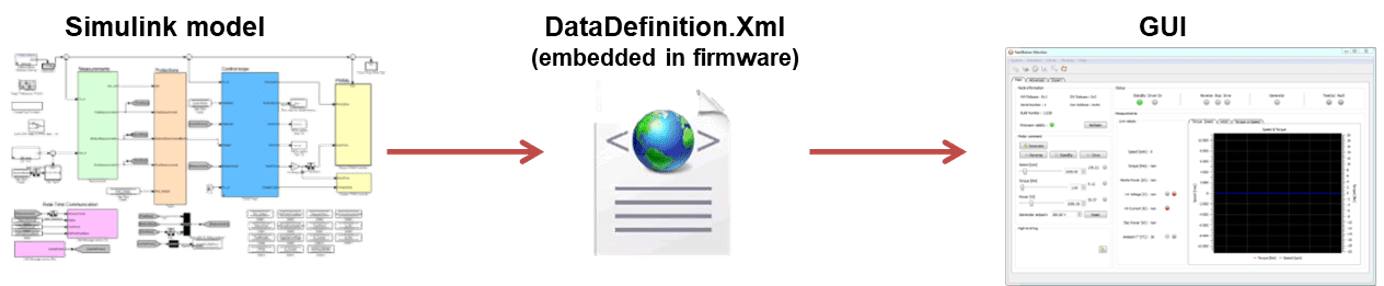

Model-Based Design

The whole electrical architecture –or a part of it– is modeled with MATLAB/Simulink. This is the starting point to perform scenario based simulations to verify the equipment performance and compliance with system requirements.

Through Simulink, we model the whole electrical architecture, or a part of it. We simulate your scenario and verify that the proposed architecture and equipment performance enable meeting your functional expectation. Our simulations can include studies on high voltage bus stability, motor drive performance, power consumption or any other critical point of your architecture.

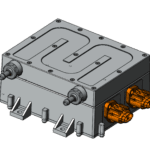

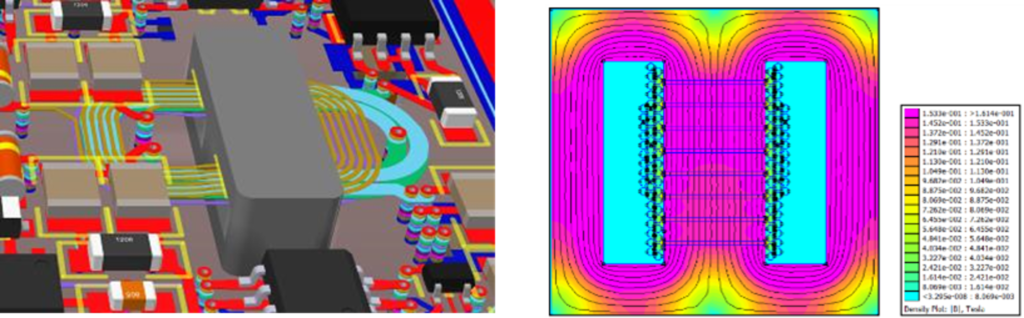

Hardware Design

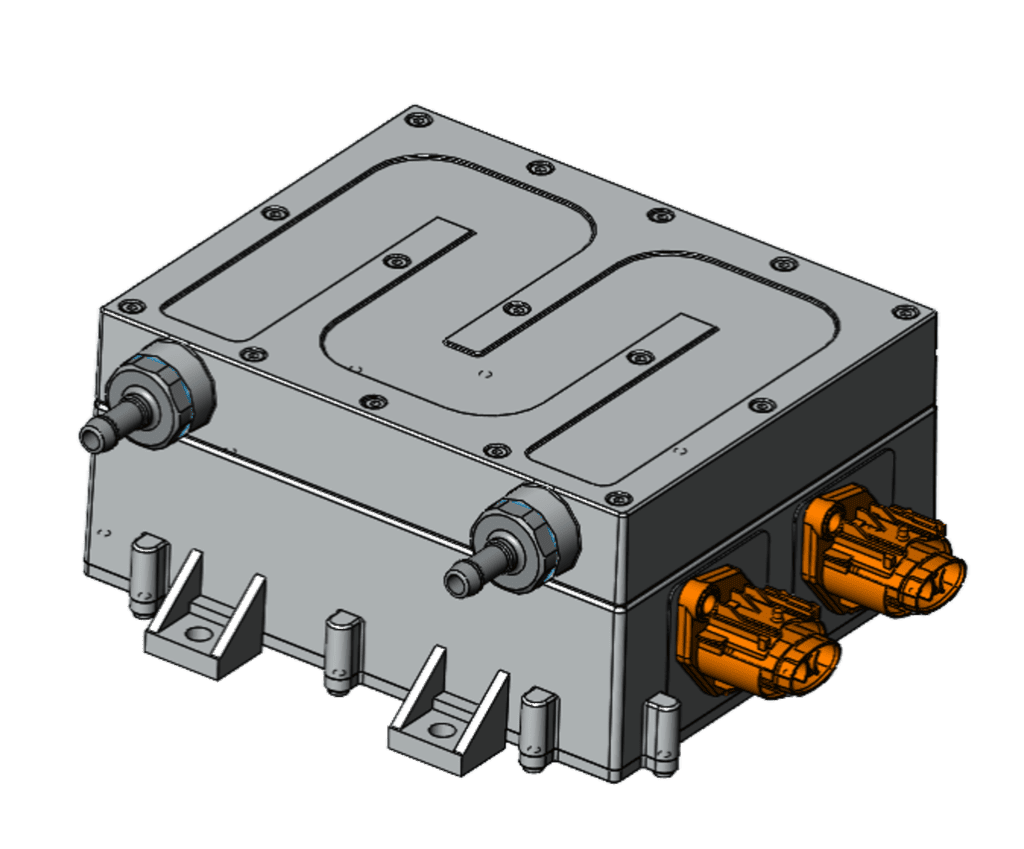

We chose the best topology to meet your requirements (performances, environment, form factor, cost). We size the power components by calculation, simulate the HW (LT spice, PSIM), and the control loops (MATLAB Simulink), as well as providing a footprint for the system (Solidworks). We provide an electrical and mechanical design to let you visualize the virtual outcome of your product.

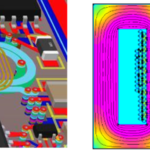

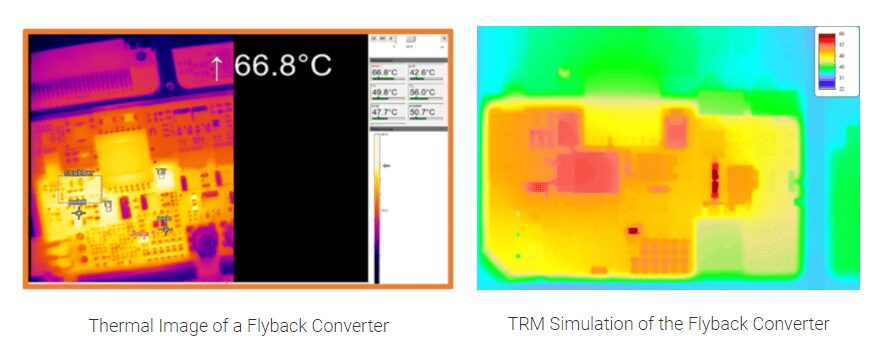

Thermal Simulation

Once schematics and layout are finished, one question frequently arises: what is going to be the temperature of the board? At Watt & Well we can answer those at ease, using thermal calculation and a finite element method (FEM) software such as TRM™ by ADAM Research.

Using this tool, our engineers can obtain a complete thermal analysis of a PCB, try different heatsinks (with or without forced convection) and optimize your circuit to get your product within the specified margins.

Additionally, CFD (Computational Fluid Dynamics) flow simulations can be used to further simulate liquid and air cooling (with or without forced convection).

Lab testing with thermal cameras is used to validate simulation data. Our model is ready to iterate towards an optimized end-equipment. At Watt & Well, we take thermal management seriously!

Software Design

Depending on your requirements, our services may involve firmware and software developments.

This includes code generation from Simulink, the C code development of drivers and communication stacks, the C++ development of the graphic user interface, the HDL design of companion chips and mission-critical apps. Software design is done in house with our own developer team.

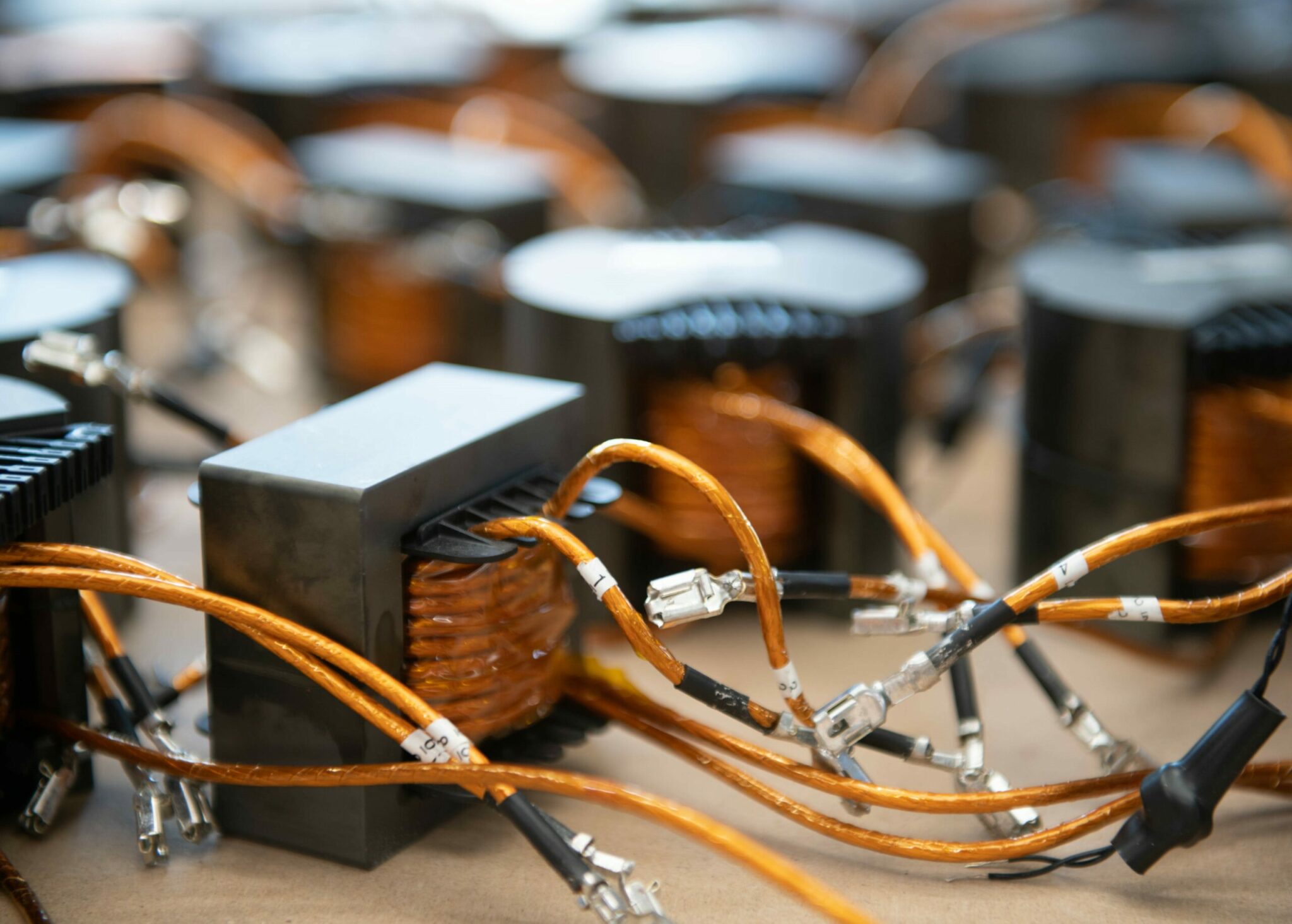

Prototyping

In-house prototyping allows fast, easier iterative work on the prototype,

to improve and debug it. These capabilities include qualified personnel and equipment for :

- PCB boards including CMS mounting and rework

- Magnetics winding, assembly

- Magnetics testing and characterization, including high voltage dielectric, impedance testing, thermal characterization. See our Magnetics Losses Management and Prototype testing

- Software design including topology modeling, control design and synthetizing (model based design)

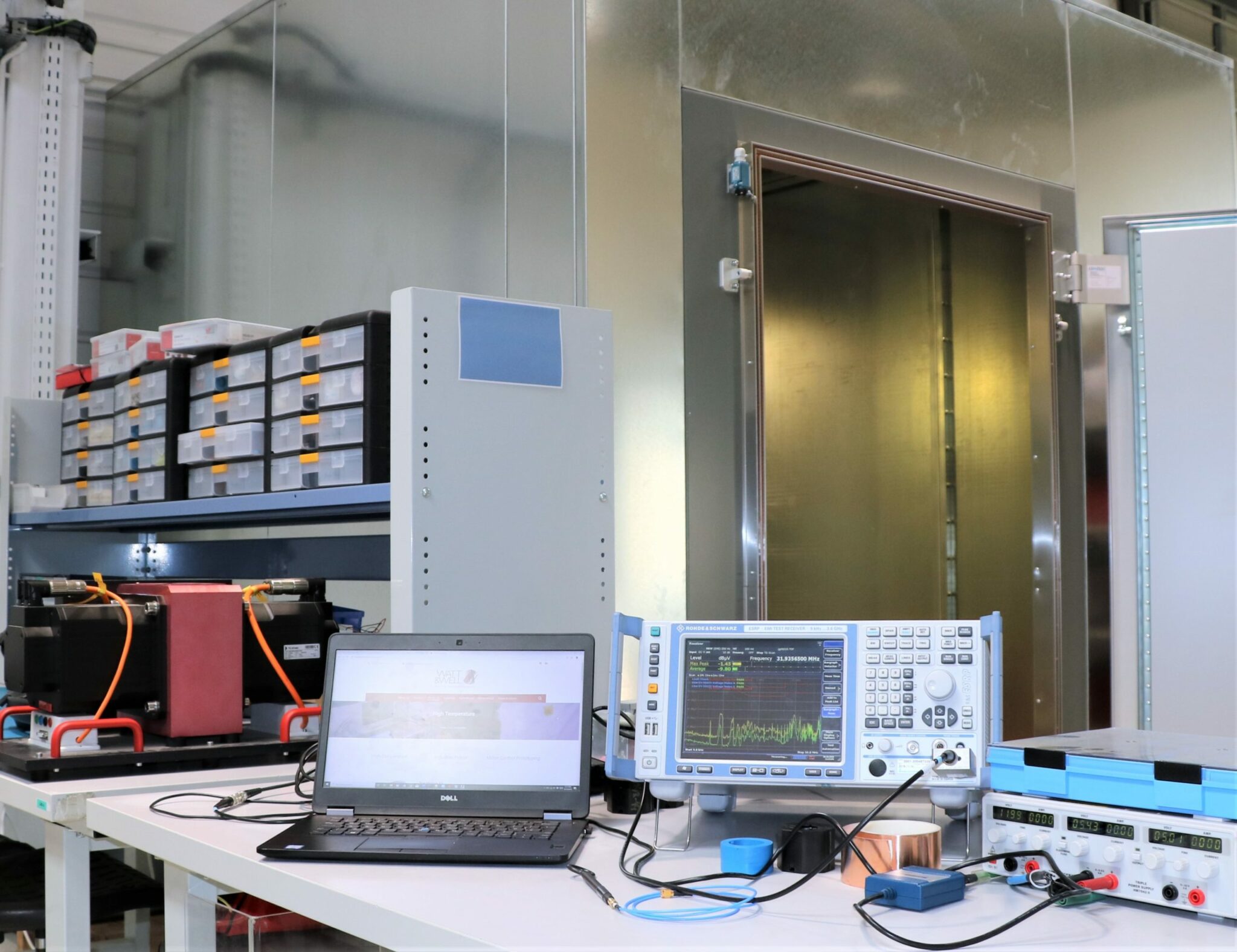

Qualification

We test the prototypes and validate the expected performances according to an acceptance test plan that has been accepted by the customer.

To ensure the reliability of our solution regarding specific environments, we qualify and validate temperature, vibration, shocks, EMI, radiation, lifetime, thermal cycling.

On-site integration

We give the necessary technical support to the team in charge of the system integration as well as documented training courses.

Industrialization – Production

Our Production and testing facilities in south of France can manage the manufacturing of 10 units up to 15 000 units a year. Boards assembly is done by one of our qualified sub-tier suppliers. Final integration, final tests and burning test are done in-house.

Customer Services

We believe our role continues well after delivery and the customer is satisfied. Aftersales services team is always available to follow up with any of your inquiries and requests. Converting power into confidence.