The best-in-class technology

We make your challenges our own, by inventing the energy applications of the future.

Our expertise in power electronics and EVSE communication protocols enables us to provide best-in-class EVSE equipment.

Hardware Design

Power electronics design such as single-phase and three-phase PFC (Power Factor Correction) converters in addition to DCDC converters and magnetics design are at the heart of Watt & Well expertise.

Over the years we developed different high frequency converters using wide bandgap semiconductors (SiC/GaN).

Working between the electronic and mechanical design domains brings unique challenges. Our eCAD team uses Altium Designer for schematic capture and PCB design. As for the mechanical design, mCAD layout is done using SolidWorks / CATIA software.

Software Design

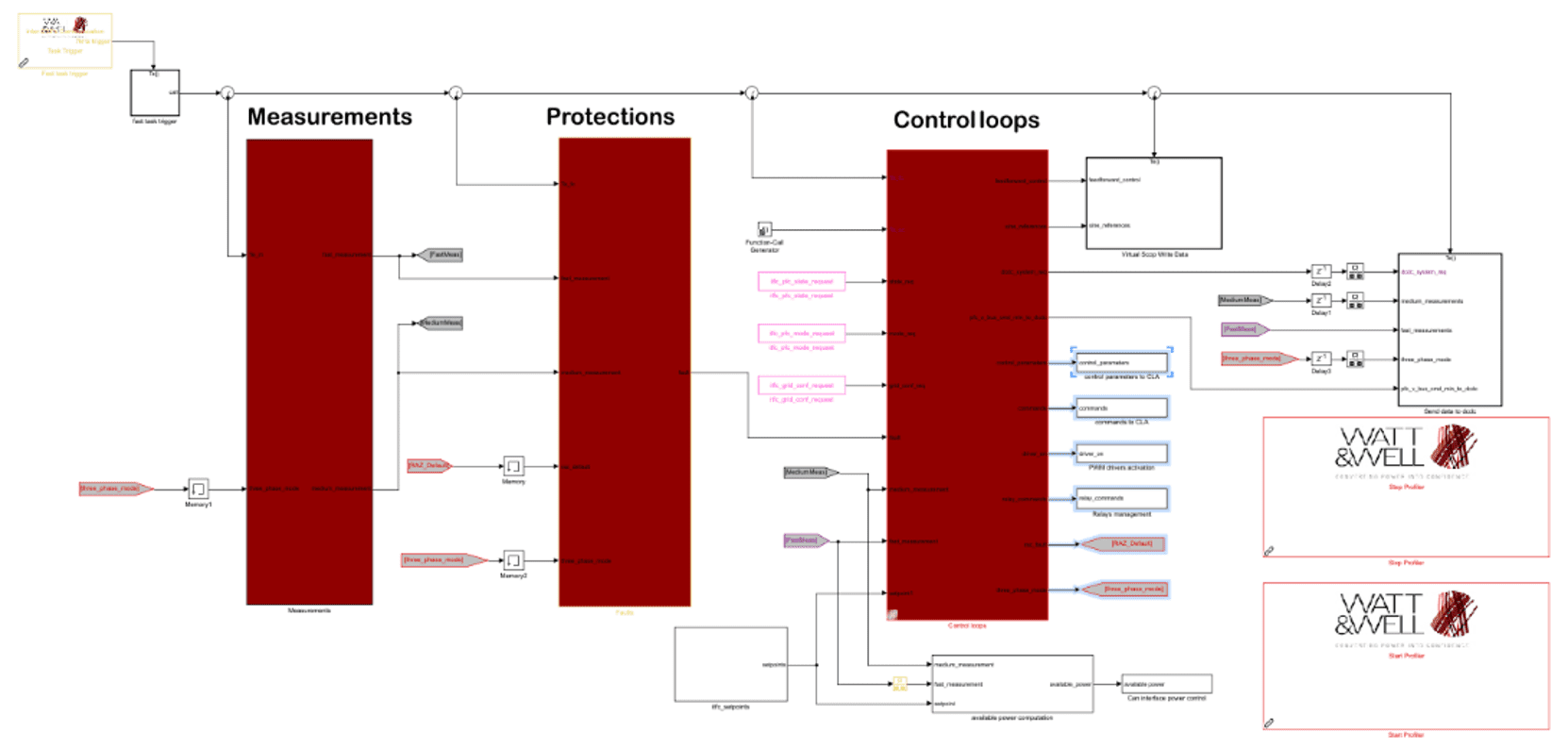

Software Workflow for power electronics

Watt & Well embedded power units rely on self-developed real time software. Applicative software containing control loops, global state machines and protections are developed through Matlab/Simulink. Low levels drivers driving the peripherals are manually coded in C and integrated into the model. All this workflow allows fast software development and short release cycles. Furthermore, the model can be easily simulated to test, for instance, the control loops stability. Watt & Well therefore disposed directly of a very reliable model which is critical in power electronics.

Cybersecurity

At Watt & Well, a special attention is paid to cybersecurity issues. It is expected to grow continuously in the coming years. Some of our products already integrate a cryptographic component and safe boot to secure EV/EVSE transactions.

Communication protocols

A team is dedicated to the SECC/EVCC softare development, mastering protocols such as 61851, 15118-2, 15118-20 and OCPP. All our software provides deep logging capabilies, enabling remote troubleshooting and continous improvement.

Graphical User Interface

A GUI interface is developed for each of our products. This interface gives visual feedback about the processes. Measurements, state feedback and some debug tools are available to the user. It also allows the commands and control through some basic widgets. This interface implements CANopen protocol as each of our products.

Vérification and validation

Verification and validation are key topics in product development. At Watt & Well, we believe in continuous integration. More and more actions are taken to improve our ways to develop new features. Each of our software are under a versioning system. At each commit a sequence of non-regression tests will be played using Jenkins.

Vérification and validation

Verification and validation are key topics in product development. At Watt & Well, we believe in continuous integration. More and more actions are taken to improve our ways to develop new features. Each of our software are under a versioning system. At each commit a sequence of non-regression tests will be played using Jenkins.

EMC filters

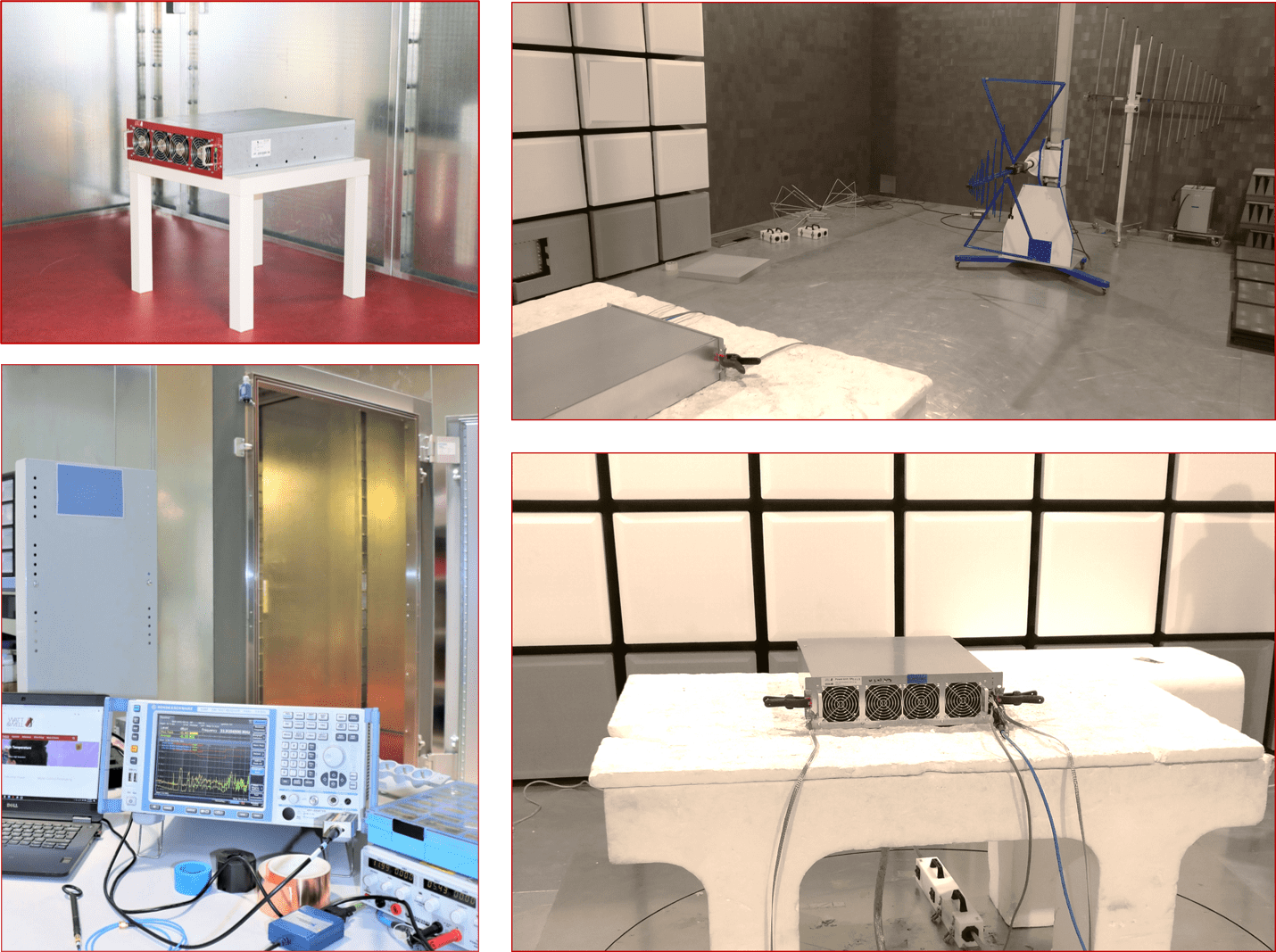

EMC design

Our expertise also covers input and output EMC filter design for power modules converters.

We, at Watt & Well, also guide our key customers through a design review of their own products and assist them to pass the rigid requirements of EMC testing. Watt & Well R&D center has an in-house electromagnetic compatibility (EMC) test lab for faster development time and quicker design iterations.

Our EMC lab is fully equipped for high power testing including an EMC cage, 100A RF shielded filters (three-phase and neutral), 63A LISNs, a 44kVA isolation transformer and a number of active loads and passive loads (up to 50kW).

Shielding effectiveness and test equipment are verified and calibrated periodically for conducted emissions pre-compliance and compliance tests.

EMC Compliance

EMC pre-compliance tests that can be done at our R&D center are:

- Current harmonic compliance: Typically regulated in the IEC 61000-3-12 (or IEC 61000-3-2 for ≤16A) where harmonics limits are imposed up to 2kHz

- Conducted emissions: typically starting at 150kHz (or 9kHz) and up to 30 MHz (108 MHz in some cases)

- Radiated emissions: Typically starting at 30MHz and up to 1GHz. Permissible levels of radiated emissions generated by an end product are regulated by numerous governing bodies.

- Dielectric withstand tests (AC or DC voltage test)

- Resistance to electrical disturbance tests: fault ride-through, transient over-voltages, voltage fluctuation, AC line impedance

We have the expertise to design converters according to these rules, so our products are CE marked (and optionally UL/CSA), and can be connected to grid or vehicle without compatibility issues.